| Introduction |

|

General Purpose Tank

Valves

- Not Recommmended For

Winemaking or Brewing -

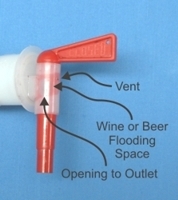

General purpose tank valves can be installed in

BetterBottle carboys as easily as they can be installed in any other

type of carboy. However, BetterBottle does not recommend their use

for winemaking or brewing: 1) They typically seal against the

outside walls of carboys or pails, leaving the crevices associated

with the threads and nuts on the inside of the container; 2)

Maintaining their proper orientation while tightening their seals is

problematic, even with a specilaized tool, because the nuts are not

easily accessible inside a carboy; 3) They cannot be adjusted for

variable sediment levels; 4) They will not drain the last 2 inches

(5 cm) of liquid from a carboy without tipping the carboy and

potentially disturbing sediments, because they cannot be installed

any lower; 5) They can be difficult to disassemble for cleaning and

sanitizing; 6) They may not be made of materials intended for

winemaking and brewing; 7) It can be difficult to connect hoses or

bottling stems to them; and 8) Some are not designed with elastomer

compression seals, so a film of wine or beer is likely to

communicate between the inside of the carboy and the valve outlet

when the valve is in the closed positon - a situation that is very

likely to cause the wine or beer to become

contaminated.

SimpleFlo™ Valve

System

- Attached to Adjustable

Carboy Racking Adapter -

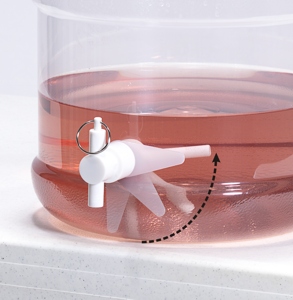

The BetterBottle

SimpleFlo™ Valve and BetterBottle Racking Adapters (see the

Racking

Adapters tab at the left side of

this page) make up the first valve system for carboys and

pails that truly addresses the specialized needs of home winemakers

and home brewers. This system makes it possible to rack and bottle

professionally, without siphons or pumps. The components are

constructed of an incredibly tough, proprietary PET that does not

stain or impart flavors and is easily cleaned and sanitized.

SimpleFlo Valves have a simple flow path, to prevent

clogging. They are simple to operate. They are simple

to disassemble and reassemble, making thorough cleaning and

sanitizing especially easy. And Viton elastomer O-rings, which are

amazingly resistant to harsh chemicals, are used to achieve tight

compression seals. But that is not all. SimpleFlo Valves are also

designed to rotate in BetterBottle Racking Adapters - hoses can be

attached even when a carboy is on the floor. And 3/8" OD polyolefin

tubing and bottling stems plug directly into SimpleFlo Valves (see

below).

Additional Information -

Use the popup menus associated with the Racking Adapter and SimpleFlo

Valve tabs at the left side of

this page for random access to all the specific information relating

to the SimpleFlo Valve and BetterBottle Racking Adapters for carboys

and pails. Use the How-To

Tips tab at the left side of this

page for information about how to use BetterBottle

components.

Chemical Resistance of

BetterBottle SimpleFlo Valves - In

general, avoid very strong caustics, such as KOH and NaOH (lyes),

and concentrated aliphatic ketones (e.g., essence oils). For

additional materials specifications, please refer to the

Technical tab at the top of this page.

Super Stainless Pull-Ring

& Clip - In 2005, BetterBottle

began making the pull-rings and clips for SimpleFlo valves from an

especially corrosion resistant stainless steel. To replace older

pull rings and clips order a BB-VALVE(HF)-SERV service kit (see

below) from your dealer. Super Stainless Pull-Ring

& Clip - In 2005, BetterBottle

began making the pull-rings and clips for SimpleFlo valves from an

especially corrosion resistant stainless steel. To replace older

pull rings and clips order a BB-VALVE(HF)-SERV service kit (see

below) from your dealer.

|

|

Description |

|

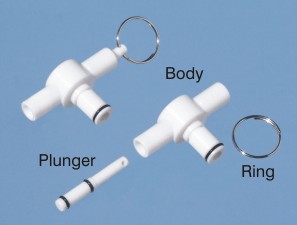

The BetterBottle SimpleFlo valve can be used

in line with hoses or as an outlet for pails and BetterBottle

carboys. The valve can be opened for partial or full flow and closed

in the blink of an eye. Its wide, simple flow path resists clogging

and it can be disassembled and reassembled for cleaning or

inspection in a matter of seconds - without

tools.

|

|

|

|

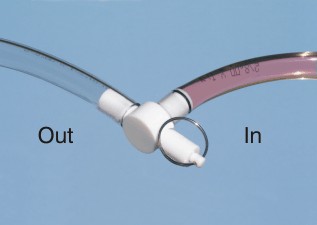

| In-line Use

of SimpleFlo Valve |

Components

& Assembly | |

|

Note: SimpleFlo

valves operate well under a wide range of conditions; however, they

may develop leaks if they are subjected to temperatures in excess of

75° C (167° F).

|

| Operation |

|

|

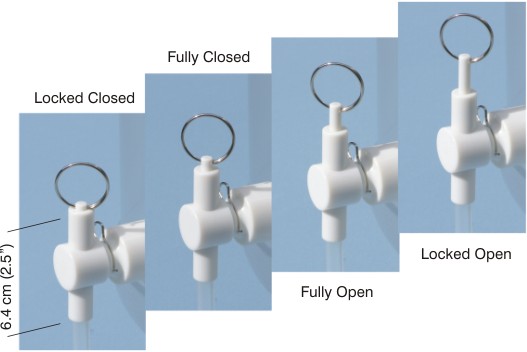

The SimpleFlo valve is designed to lock in the

closed or open position by moving the plunger as far as it can

travel in the appropriate direction (see image below). A slight

increase in resistance to the movement of the plunger near the

limits of travel signals the transition from adjustable flow to a

locked position. When a valve is being opened and closed repeatedly

at short intervals, it is not necessary to move the plunger all the

way to a locked position; however, it should be locked if it is to

be left unattended. |

|

|

|

The input of the SimpleFlo valve

is primarily designed to mate in quick-disconnect fashion with

BetterBottle Racking Adapters for carboys and pails (see the

Racking Adapter tab to the left of this

page); however, the input will also push into 1/2" ID tubing. The

output side is designed to make connection with food-grade 1/2",

3/8", and 1/4" ID polyolefin tubing (see

figure below) as well as 3/8" OD bottle filling tubes (see the

How-To Tips tab to the left of this

page). BetterBottle does not recommend vinyl and rubber tubing (see

the Tubing

(PET-Lined) tab to the left of this page)

Hose clamps

should not be necessary for low-pressure applications. If clamps are

necessary, use plastic clamps. Metal screw clamps can apply uneven

pressure to small-diameter tubing and distort the bodies of

SimpleFlo valves.

Note: Never use pliers or other

mechanical gripping devices to install or remove

tubing. |

|

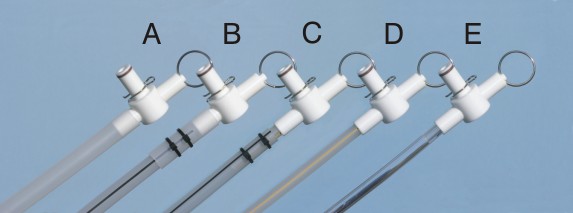

A) 1/2" ID PET-lined tubing

pushes over the output port. B) 3/8" ID PET-lined tubing can

be coupled to the output port with a short length of 1/2" ID

PET-lined tubing. C) 3/8" ID PET-lined tubing can be coupled

to the output port with a short piece of 1/4" ID PET-lined tubing.

D) 1/4" ID PET-lined tubing pushes into the output port.

E) Soft 3/8" ID tubing is coupled to output port with a short

piece of 1/4" ID PET-lined tubing.

|

| Cleaning /

Sanitizing |

|

The special PET from which BetterBottle

SimpleFlo valves are made has a non-porous, hydrophobic surface,

making it extremely easy to clean and sanitize. SimpleFlo valves may

be damaged by temperatures exceeding 75° C (167° F). Read the

Wash/Sanitize section, under the Technical tab

at the top of this page, for important informaton.

The PET is very tough and will not scratch easily, but take

precautions not to scratch the precision, smooth, sealing surfaces.

Always rinse SimpleFlo valves thoroughly in clean water before

storing them.

Abrasive scouring pads and cleansers should

never be required or used.

Soaking metal parts in

cleaning or sanitizing solutions can cause corrosion - they should

be removed.

Service

- It should not be necessary to remove

SimpleFlo valve O-rings for routine cleaning and sanitation. If an

O-ring requires replacement, do not use sharp tools that might cut

the O-ring or scratch the walls of the groove. Pinch a short segment

of the O-ring into its groove with a finger nail and use the other

hand to rub the rest of the O-ring around the groove and toward the

pinch. The O-ring will stretch and bulge up so it can be rolled out

of the groove. Use only BetterBottle O-rings for replacement; they

are made of special materials that cannot be easily obtained through

hardware suppliers and other materials may not function

correctly.

If a SimpleFlo valve leaks at point #2, the

SimpleFlo valve plunger is not sealing properly. To disassemble a

SimpleFlo valve, rotate the wire ring through the hole in the end of

the plunger shaft, pulling the end of the wire slightly to the side,

so the ring unscrews out of the hole (see assembly photo

under Description above). Then, push the plunger out the end of the

valve body. Check the O-rings for cuts and the valve bore for

scratches or debris by looking down the bore toward a source of

light. If the O-rings and bore appear to be in good condition, check

the O-ring grooves for scratches or debris. To reassemble the valve,

push the plunger into the valve body and screw the wire ring

back through the hole in the end of the plunger shaft by pulling the

end of the wire slightly to the side.

| If

a SimpleFlo valve / Racking Adapter assembly leaks at point #1,

there are a number of possible causes: 1) The large O-ring on the

SimpleFlo valve has been damaged or its groove is scratched or

dirty, 2) The bore of the Adapter is scratched where it seals with

the large O-ring on the SimpleFlo valve, or 3) The Racking Adapter

is not sealing against the inner wall of the carboy or pail and

liquid is creeping along the thread of the Racking Adapter to the

first point where it can escape, which is at point #1. If the first

and second causes can be ruled out, recheck the installation of the

Racking Adapter (see the Racking

Adapter tab to the left of this

page for service advice).

To confirm that the valve seals of a SimpleFlo

valve / Carboy Racking Adapter assembly are in good condition, use a

hose to connect the stem of the Adapter to a faucet and apply water

pressure. A pressure of between 1 and 2 bar (15 and 30 PSI) is

recommended. Higher pressures may cause the valve to pop out of the

Racking Adapter. Open the SimpleFlo valve to let the connecting hose

fill with water and then close the valve, dry off the parts, and

check for leaks.

If a pull-ring or

clip shows signs of corrosion, order a set of repair parts (see Part

Numbers below) and replace them. The pull-ring and clip are

currently made of very corrosion-resistant stainless steel.

|

| Part

Numbers |

|

SimpleFlo™ Valve -

BB-VALVE(SF)

Replacement set of O-rings, retainer clip,

and pull ring for SimpleFlo Valve - BB-VALVE(SF)-SERV

|

| Packaging |

|

Harmonized System Code - 3923.30.90.90

applies to these parts

BB-VALVE(SF)

-

Individually packed in a hang-hole,

zipper bag

Bags of 20 individual

packages - 1.41 lbs (0.64

Kg)

| |