Introduction

BetterBottle PET carboys and fittings have a great many

advantages when compared with glass carboys. Advantages such as safety,

light weight, and ease of cleaning are obvious and result in automatic

benefits; however, many other advantages are of no benefit unless they are

actively applied. The following tips explain how to apply BetterBottle

products to their best advantage. Use the tabs to the left of this page

for detailed information about the installation and maintenance of

specific items.

Handles

Lifting a

filled 5 gallon carboy by its neck will apply a tensile (stretching) force

of at least 55 lbs (~24 Kg) to the narrowest part of the neck. Glass

carboy should never be lifted by handles attached to their necks,

especially when they are full, because the tensile (pulling) strength of

glass is not predictable. Glass that has been scratched or etched (i.e.,

washed with caustic detergents) is especially likely to crack. However,

the necks and shoulders of BetterBottle carboys are designed for high

tensile forces. Handles make moving filled carboys much easier and

BetterBottle recommends several. Use the Handles tab to the

left of this page for specific information about

handles.

When a BetterBottle carboy is

raised off a surface by lifting its neck, the weight of the contained

liquid will cause the carboy to flex slightly. This flexing can suck

liquid out of liquid-filled air locks. BetterBottle recommends using

DryTrap air locks. Alternatively, the outlet of a liquid-filled air lock

can be closed off with a stopper when a carboy is being lifted. Use the

DryTrap

tab to the left of this page for specific information about DryTrap air

locks.

Closures

Vinyl caps

and #10 stoppers fit the necks of BetterBottle carboys better than they

fit the often irregular necks of glass carboys; however, these soft

closures suffer from numerous drawbacks, primarily related to flavor

scalping (adding undesirable flavors). Use the Technical tab at the

top of the page to learn more about flavor scalping. BetterBottle

Universal and the Big Blow closures are made of PET. They do

not scalp flavors and use Teflon-encapsulated ,Viton O-rings to create

precision seals that require no lubrication. BetterBottle closures are

also designed to make it easy to rack under the low-oxygen, or

oxygen-free, conditions described below. Use the Closures tab to the

left of this page for more detailed information.

|

Labeling

|

|

Plastic post-it labels, which are available

in a variety of colors, or easy-release masking tape (usually blue

or green) make convenient, easily removed identification labels.

Plastic cable ties, which are also available in a variety of colors,

make color coding easy and can be used to attach tags to the necks

of the carboys. Fast-drying marking pens of the sort used to label

CDs or DVDs can also be used and the writing can be removed with

ethanol. Do not experiment with other solvents; they may cause

Environmental Stress Cracking (ESC). See the Wash/Sanitize

and Materials sections under the Technical tab

at the top of this page for additional information about

ESC.

|

A typical, 2 cm X 16 cm, dual-scale (4°C -

28°C / 39°F - 82°F) liquid crystal strip will fit all three sizes of

BetterBottle carboys. Furthermore, testing by BetterBottle indicates

that the special PET used to make BetterBottle carboys conducts heat

sufficiently well so the strips can indicate the temperature of the

contained liquid within a fraction of a degree, even when the

ambient temperature is 20°C higher or lower. In fact, strips can be

attached to BetterBottle carboys with clear tape, leaving the paper

liner that protects the adhesive of the strips in place, without

affecting the accuracy of the strips to a significant extent. The

tape should be just a little wider than the strips, so the strips

are held firmly to the surface of the carboys. It is easy to remove

strips attached with clear tape and the clear tape comes off the

smooth face of most strips very easily.

As a general rule,

it is wise to calibrate strips when

controlling temperatures to within a relatively narrow range is

critical. |

|

|

|

Filling

Before

filling a BetterBottle carboy with juice or wort the carboy should be

washed, sanitized, and rinsed. Use the Technical tab at the

top of this page for specific information and tips about cleaning and

sanitizing. If the carboy is equipped with a Racking Adapter and SimpleFlo

valve, test the seals by filling the carboy with water. Use the

Racking Adapter tab to the left of this page for troubleshooting

information.

Very Important Brewer's

Note: Pour a generous portion of the cold

diluting water to the BetterBottle carboy before adding the wort and be

very certain that the wort has been chilled so it is cool to the touch.

Mix the wort with the water right away (see

Mixing/Oxygenating/Degassing below). Do Not chill hot wort

in BetterBottle carboys and do not pour undiluted wort into BetterBottle

carboys – doing so appears to promote environmental stress cracking (ESC).

For more details about ESC, see the Wash/Sanitize section, under

the Technical tab at the top of this page.

BetterBottle offers a sturdy funnel that fits snugly into the

wide necks of all BetterBottle carboys. There is no bubbling around the

stem during fast filling and none of the slopping that occurs when funnels

rock back and forth. Use the Closures

& Funnel tab to the left of this

page for additional information.

Sudden

temperature changes will not cause BetterBottle carboys to crack the way a

glass carboy does. However, do no fill BetterBottle carboys with liquids

that are above 60°C (140°F). At 60° C, skin will be burned severely in

about 6 seconds and higher temperatures will not give time to react.

Furthermore, higher temperatures can damage the carboys. See the

Materials section under the Technical tab at the

top of this page for additional safety and materials

information.

|

Using Liquid Crystal Temperature

Strips

A typical, 2 cm X 16 cm,

dual-scale (4°C - 28°C / 39°F - 82°F) liquid crystal strip will fit all

three sizes of BetterBottle carboys. Furthermore, testing by BetterBottle

indicates that the special PET used to make BetterBottle carboys conducts

heat sufficiently well so the strips can indicate the temperature of the

contained liquid within a fraction of a degree, even when the ambient

temperature is 20°C higher or lower.

|

Mixing/Oxygenating/Degassing

Agitating the unsettled contents of BetterBottle carboys in

order to mix ingredients, add oxygen, or remove CO2 is very

simple and, in contrast to glass carboys, no special equipment is

required. If the wine or beer has already been settled in preparation for

racking, slapping the side of the BetterBottle carboy will cause shock

waves that will drive CO2 out of the liquid and hasten the

settling of low density suspended or clinging solids – without

significantly disturbing the sediment on the bottom of the carboy. To

prevent oxygen contamination during degassing, carboys should be closed or

equipped with a DryTrap air lock. Use the DryTrap tab to the

left of this page for detailed information.

|

| A BetterBottle carboy can be

placed on a cloth or towel and shaken (short rolls) back and forth

to slosh the contents vigorously with very little effort. Leave

extra head space during initial mixing and aeration to maximize

agitation. Tune your rocking motion for the desired effect; very

hard rocking may result in less efficient mixing than more gentle

rocking. |

|

|

|

| Swirling the contents

of a BetterBottle carboy vigorously requires almost no effort, if a

tennis ball is placed in the punt space under the carboy. Do not

tilt the carboy by so much that the edge of the carboy's base

touches the surface (see Important Note). And perform the swirling

on a smooth or soft surface for good measure. Leave extra head space

during initial mixing and aeration to maximize agitation. Tune your

swirling motion for the desired effect; very hard swirling may

result in less efficient mixing than more gentle swirling.

Important Note:

Never rock or swirl BetterBottle carboys without using a tennis

ball. Doing so will cause the edges of the bottom of the carboy to

repeatedly crease and flex, causing a great deal of stress in the

PET that may eventually cause cracks, like bending a paper clip back

and forth. |

Fermenting

When a

carboy is equipped with a Racking Adapter, the adapter should be adjusted

so the stem angles slightly downward (hour hand at about 3:30 or 8:30)

during fermentations in order to prevent solids from settling into the

bore of the stem. If an adapter or valve does become blocked, there are

simple procedures for clearing it (See Racking below).

BetterBottle carboys are well suited for primary fermentation

as well as secondary fermentation and clarification. There are a number of

advantages to performing primary fermentations in BetterBottle carboys

rather than plastic pails: 1) BetterBottle carboys are clear, so it is

possible to see how a fermentation is proceeding and to rack more

effectively; 2) The tapered shoulder of the carboy results in better

removal of foam, which can contain undesirable components (e.g., volatiles

and denatured substances) that are best removed (i.e., kraeusen); and 3)

Plastic pails are injection molded and are likely to be made of materials

that impart, or carry over, strong flavors.

Wine and beer kits may call for primary volumes that fill

BetterBottle containers so full that the surface area is insufficient for

the initial aerobic stage of fermentation or even modest foaming would

cause excessive loss of liquid. In these cases, begin primary fermentation

under slightly concentrated conditions and dilute to the recommended

volumes once the initial rapid fermentation subsides.

Many juices produce only a modest foam during primary

fermentation and there is no need for a blow hose. However, if foam rises

to the point that it would enter the air lock, switch to a blow hose until

the foam subsides. BetterBottle Universal Closures will accept an 11 mm

(1/2") OD tubing, which should serve nicely as a blow hose for even the

most foamy strained juices. Juices and worts that contain solids are

likely to require a larger opening; the BetterBottle Big Blow Closure is

designed for these cases. Use the Closures & Funnel tab to the left of this page for information about blow

hoses. BetterBottle recommends keeping blow hoses as short as possible and

placing their open ends into a small, short glass in a sink or basin.

Liquid in the glass will serve as a trap and overflow will run into the

sink, where it can be easily rinsed away, or into the basin. As soon as

foam no longer rises into the neck of the carboy, replace the blow hose

with an air lock, preferably a BetterBottle DryTrap. DryTrap air locks are

particularly well suited for use with BetterBottle carboys; they will no

blow out or suck back and they can play an important role during racking

(see below). Use the DryTrap tab to the

left of this page for specific information about DryTrap air locks.

In order to minimize the number of times

a carboy is opened during fermentation, BetterBottle recommends placing a

hygrometer in the carboy when the air lock is installed. If a carboy is

equipped with a Racking Adapter and SimpleFlo valve, test samples of the

wine or beer can be drawn through the valve.

If solid items (e.g., oak chips, elderberry, etc.) are added

for flavoring, BetterBottle suggests placing them in a winemaker's tea

bag to prevent them from floating above the sediment and being

transferred during racking.

Racking

Racking wine

or beer can certainly be done in a traditional fashion with siphons or

pumps, using plain BetterBottle carboys. However, BetterBottle Adapters

and SimpleFlo valves make racking far more convenient. They also make it

simple to rack under, closed-loop conditions to reduce, or

eliminate, oxygen contamination. It is essentially impossible to perform

closed-loop racking with siphons.

Use the

Racking Adapters and SimpleFlo

Valve tabs to the left of this page for

detailed information about these components and the connection of tubings.

Use the Tubing tab to the left of this page for information about PET-lined

tubing. Unlike conventional tubing, this special tubing does not scalp

flavors and is exceptionally easy to sanitize.

The following sub-sections provide suggestions for

performing: 1) Pail-to-carboy, open racking; 2) Carboy-to-carboy,

low-oxygen, closed-loop racking; and 3) Carboy-to-carboy, oxygen-free,

closed-loop racking. The steps for the three approaches are so

similar that they could be integrated; however, in the interests of

clarity and because there are so few steps, each of the approaches is

described independently.

In all three

approaches, the bottom of the full (input) carboy, or pail, should be

positioned well above the top of the output (empty) carboy. When the input

carboy, or pail, is placed on a 1 meter (39 inches) high counter and the

empty carboy is placed on the floor, the wine or beer will flow at about

2.5 liters/min using 1/4" ID PET-lined tubing and 4 liters/min using 3/8"

ID tubing. BetterBottle recommends using the smaller ID tubing and taking

a couple extra minutes, because racking too quickly only makes it

difficult to rack cleanly.

Important: Racking flow will

be greatly reduced if a bubble of gas becomes trapped in the tubing

through which liquid is being transferred. In the case of 1/4" ID

PET-lined tubing, the gas in the transfer tubing will essentially always

be pushed out by the flow of liquid. Sometimes, gas will trap in 3/8"

PET-lined tubing, but it can be coaxed out by tapping the tubing at

various points while the liquid is flowing. Removing trapped gas from 1/2"

ID siphon tubing can be a nuisance.

|

|

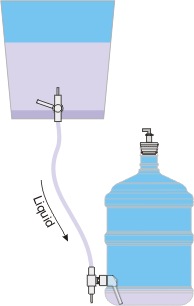

Pail-to-Carboy (Open)

Racking

Racking from a pail,

fitted with a BetterBottle Pail Adapter and SimpleFlo valve, into a

BetterBottle carboy, fitted with a Racking Adapter and SimpleFlo

valve, entails little more than connecting a tubing.

|

- Prepare a sanitized output (empty)

carboy and insert a sanitized DryTrap air lock.

- If there is any doubt about whether

or not the outlets of the SimpleFlo valves are sanitized when you

are ready to begin racking, take a moment to sanitize and rinse

them. The valves can be rotated, so it is easy to sanitize and

rinse their outlets with a small squirt bottle or a dropper. A

sponge or cup can be used to catch drips. Rotate the outlets of

the valves downward to drain any residual rinse water.

- Rotate the Racking Adapter of the

carboy so the opening of the adapter's internal stem is pointed

downward, but not quite straight down.

- Prepare an appropriate length of

sanitized transfer tubing and connect the valves together.

Refer to the schematic drawing to the right. The transfer

tubing should be just a little longer than necessary to make

the connection. The valves can be rotated to prevent interference

with the surfaces on which the pail and carboy have been placed

and to minimize the length of tubing required.

- Open the valves to permit the wine

or beer to transfer from the pail into the carboy.

- If there is only a little sediment

in the pail, tilt the pail slightly to recover more clear

liquid.

- To recover the liquid remaining in

the transfer tubing at the end of

racking:

- Close the output carboy's

SimpleFlo valve and press down lightly on the shoulder of the

carboy for a moment to expel some air from the carboy through

the DryTrap air lock (a one-way valve); thereby, creating a

slight vacuum inside the carboy.

- Partially open the carboy valve

until the liquid remaining in the tubing has been drawn into the

output carboy. If some liquid remains in the tubing, repeat

these last two steps.

Carboy-to-Carboy

(Closed-Loop) Racking

Racking between two BetterBottle carboys, fitted with

Racking Adapters and SimpleFlo valves, can be done in exactly the

same open manner as racking from a pail to a carboy. However, the

adapters and valves make it so easy to rack between carboys under

closed-loop conditions that there is no reason to rack any

other way. Racking under low-oxygen, closed-loop conditions

requires no advanced planning or preparation, and racking under

oxygen-free, closed-loop conditions requires only minimal

advanced planning and preparation.

|

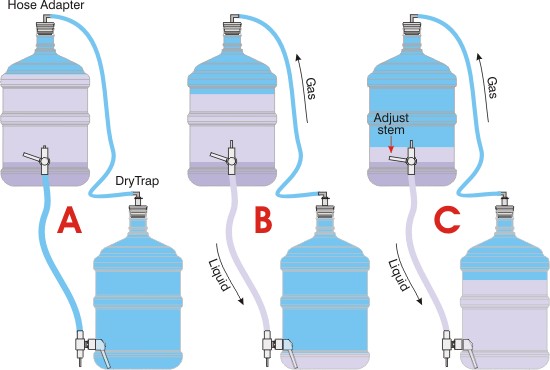

Low Oxygen

All you need in order to rack under low-oxygen,

closed-loop conditions is two short lengths of

tubing.

Simple

Closed-Loop Racking

- Prepare a sanitized output

(empty) carboy and insert a sanitized DryTrap air

lock.

- If there is any doubt about

whether or not the outlets of the SimpleFlo valves are

sanitized when you are ready to begin racking, take a moment

to sanitize and rinse them. The valves can be rotated, so it

is easy to sanitize and rinse their outlets with a small

squirt bottle or a dropper. A sponge or cup can be used to

catch drips. Rotate the outlets of the valves downward to

drain any residual rinse water.

- Rotate the Racking Adapter of

the input (full) carboy to position the opening of the

adapter's internal stem about 1" (2.5 cm) above the sediment

layer.

- Rotate the Racking Adapter of

the output carboy so the opening of the adapter's internal

stem is pointed downward, but not quite straight

down.

- Prepare an appropriate length

of sanitized transfer tubing and connect the valves

together. Refer to step "A" in the schematic drawing above.

The transfer tubing should be just a little longer

than necessary to make the connection. The valves can be

rotated to prevent interference with the surfaces on which

the carboys have been placed and to minimize the length of

tubing required.

- Prepare a sanitized

pressure balancing tubing with a 90° hose barb

closure adapter at one end, using an appropriate length of

1/4" ID tubing, and connect the port of the input carboy's

closure to the hose barb of the DryTrap installed in the

output carboy. Refer to step "A" in the schematic drawing

above.

- Open the valves to permit the

wine or beer to transfer. Refer to step "B" in the schematic

drawing above.

- When the level of the

clarified liquid in the input carboy approaches the stem of

the Racking Adapter, rotate the stem slowly downward until

it is just above the point where sediment would start to be

drawn up. Refer to step "C" in the schematic drawing above.

Closing the valve somewhat will reduce the flow rate and

permit you to position the stem closer to the sediment

layer. If flow breaks off before all of the clarified liquid

has been recovered, you can position the stem a little lower

and easily restart the flow, even if it does not start

spontaneously.

- To restart flow that breaks

off before racking is complete and when the liquid level is

too low to flow spontaneously, or to recover the liquid

remaining in the transfer tubing at the end of

racking:

- Close the output carboy's

SimpleFlo valve and press down lightly on the shoulder of

the carboy for a moment to expel some air from the carboy

through the DryTrap air lock (a one-way valve); thereby,

creating a slight vacuum inside the output carboy.

- Partially open the carboy

valve until the liquid remaining in the tubing has been

drawn into the output carboy. If some liquid remains in

the tubing, repeat these last two

steps.

|

|

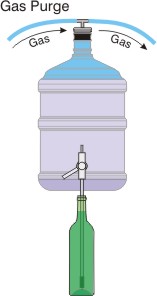

Oxygen Free

All you need in order to rack under oxygen-free,

closed-loop conditions is two short lengths of tubing

and a way of purging the oxygen from the output (empty) carboy.

The cost of renting a tank of a dense purge gas (e.g., argon,

nitrogen, or CO2) and a pressure regulator is not

great; however low-pressure CO2 costs very little,

if anything. Inexpensive dry ice (solid CO2) is

readily available from ice cream shops and many supermarkets.

However, fermenting 20 liters of wine or beer to an ethanol

concentration of 5% (ABV) will produce about 380 liters of

CO2, way more than necessary to purge a carboy –

free of charge.

Note: Before using dry ice, learn about handling it

safely and follow good safety practices. Sixty grams (~2 oz)

of dry ice, a chunk about the size of a large standard ice

cube (3.5 cm X 3.5 cm X 3.5 cm), will sublime (evaporate) to

produce approximately 45 liters of CO2, enough to

purge a closed-loop very nicely. The dry ice can be

broken up and placed in a relatively small, wide-mouth,

transparent, plastic bottle, equipped with a closure to which

a 1/2" ID tubing can be attached. Do

not use a glass or metal container and be sure pressure cannot

build up! To increase the rate at

which the dry ice evaporates, the bottle can be warmed gently

by placing it in warm water. Dry ice should not damage

BetterBottle carboys; however, BetterBottle recommends that

dry ice not be placed directly into the output carboy, because

commercial dry ice may contain solid contaminants (e.g., dust,

bits of paper, etc.)

The purge gas should be introduced

through the valve of the output carboy, because recommended

purge gases are more dense than oxygen and purging will be

somewhat more efficient. The configuration of the tubings

during the purging stage depends on the source of purge gas.

|

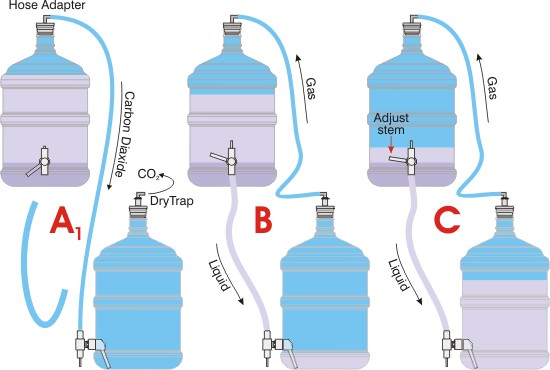

Fermentation CO2

– If the choice of gas is CO2 produced

during fermentation, a connection must be made from the

top of the input carboy to the valve of the output

carboy while fermentation remains very active.

Purged

Closed-Loop Racking (Fermentation

CO2)

- Prepare a sanitized

output (empty) carboy and insert a sanitized DryTrap

air lock.

- When you are ready to

begin purging, if there is any doubt about whether or

not the outlet of the SimpleFlo valve attached to the

output carboy is sanitized, take a moment to sanitize

and rinse it. The valve can be rotated, so it is easy

to sanitize and rinse its outlets with a small squirt

bottle or a dropper. A sponge or cup can be used to

catch drips. Rotate the outlet of the valve downward

to drain any residual rinse water.

- Rotate the output

carboy's Racking Adapter so the opening of the

adapter's internal stem is pointed downward, but not

quite straight down.

- Prepare a sanitized

pressure balancing tubing with a 90° hose barb

closure adapter at one end, using an appropriate

length of 1/4" ID tubing; connect the port of the

input (full) carboy's closure to the output carboy's

valve by pushing the tubing into the ID of the valve's

output; and open the valve. Refer to step

"A1" in the schematic drawing above. As the

DryTrap valve opens and closes with the flow of

CO2, it makes a gentle clicking, which

serves as a simple indicator that fermentation remains

active.

- When it is time to rack,

rotate the Racking Adapter of the input carboy to

position the opening of the adapter's internal stem

about 1" (2.5 cm) above the sediment layer. Refer to

step "B" in the schematic drawing above.

- Close the output

carboy's valve connect the end of the pressure

balancing tubing to the hose barb of the DryTrap

installed in the output carboy. Refer to step "B" in

the schematic drawing above.

- Re-sanitize the outlet

of the output carboy's valve.

- Prepare an appropriate

length of sanitized transfer tubing and connect

the valves of the input and output carboys together.

Refer to step "B" in the schematic drawing above. The

transfer tubing should be just a little longer

than necessary to make the connection. The valves can

be rotated to prevent interference with the surfaces

on which the carboys have been placed and to minimize

the length of tubing required.

- Open the valves to

permit the wine or beer to transfer.

- When the level of the

clarified liquid in the input carboy approaches the

stem of the Racking Adapter, rotate the stem slowly

downward until it is just above the point where

sediment would start to be drawn up. Refer to step "C"

in the schematic drawing above. Closing the valve

somewhat will reduce the flow rate and permit you to

position the stem closer to the sediment layer. If

flow breaks off before all of the clarified liquid has

been recovered, you can position the stem a little

lower and easily restart the flow, even if it does not

start spontaneously.

- To restart flow that

breaks off before racking is complete and when the

liquid level is too low to flow spontaneously, or to

recover the liquid remaining in the transfer

tubing at the end of racking:

- Close the output

carboy's SimpleFlo valve and press down lightly on

the shoulder of the carboy for a moment to expel

some air from the carboy through the DryTrap air

lock (a one-way valve); thereby, creating a slight

vacuum inside the output carboy.

- Partially open the

carboy valve until the liquid remaining in the

tubing has been drawn into the output carboy. If

some liquid remains in the tubing, repeat these last

two steps.

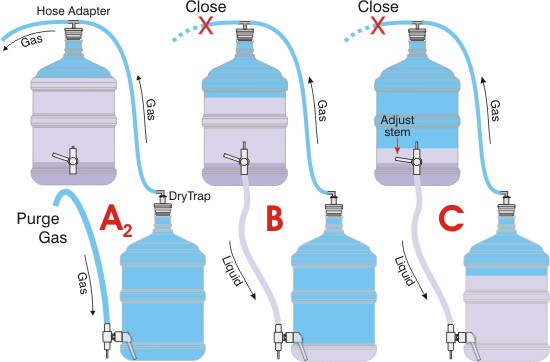

External Purge Gas – When

the source of purge gas is external, arranging to have

the gas available is the only preparation

required.

Purged

Closed-Loop Racking (External Purge

Gas)

- Prepare a sanitized

output (empty) carboy and insert a sanitized DryTrap

air lock.

- When you are ready to

begin racking, if there is any doubt about whether or

not the outlets of the SimpleFlo valves are sanitized,

take a moment to sanitize and rinse them. The valves

can be rotated, so it is easy to sanitize and rinse

their outlets with a small squirt bottle or a dropper.

A sponge or cup can be used to catch drips. Rotate the

outlets of the valves downward to drain out any

residual rinse water.

- Rotate the Racking

Adapter of the input (full) carboy to position the

opening of the adapter's internal stem about 1" (2.5

cm) above the sediment layer.

- Rotate the Racking

Adapter of a sanitized output carboy so the opening of

the adapter's internal stem is pointed downward, but

not quite straight down.

- Prepare a length of

sanitized transfer tubing that is just a little

longer than necessary to connect the input and output

carboys' valves together and connect one end to the

output carboy's valve. Refer to step "A2"

in the schematic drawing above. The valves can be

rotated to prevent interference with the surfaces on

which the carboys have been placed and to minimize the

length of tubing required.

- Prepare a sanitized

pressure balancing tubing with a "T" hose barb

closure adapter at one end, using an appropriate

length of 1/4" ID tubing, and connect the port of the

input carboy's closure to the hose barb of the DryTrap

installed in the output carboy. Refer to step

"A2" in the schematic drawing above.

- Be sure the output

carboy's valve is open and connect the source of purge

gas to the free end of the transfer tubing. Run

the equivalent of about 4 carboy volumes of purge gas

through the output carboy and pressure balancing

tubing.

- Turn off the flow of

purge gas, connect the free end of the transfer

tubing to the input carboy's valve, and close off

the open end of the "T" hose barb closure adapter in

the input carboy's closure. Refer to step "B" in the

schematic drawing above.

- Open the valves to

permit the wine or beer to transfer.

- When the level of the

clarified liquid in the input carboy approaches the

stem of the Racking Adapter, rotate the stem slowly

downward until it is just above the point where

sediment would start to be drawn up. Refer to step "C"

in the schematic drawing above. Closing the valve

somewhat will reduce the flow rate and permit you to

position the stem closer to the sediment layer. If

flow breaks off before all of the clarified liquid has

been recovered, you can position the stem a little

lower and easily restart the flow, even if it does not

start spontaneously.

- To restart flow that

breaks off before racking is complete and when the

liquid level is too low to flow spontaneously, or to

recover the liquid remaining in the transfer

tubing at the end of racking:

- Close the output

carboy's SimpleFlo valve and press down lightly on

the shoulder of the carboy for a moment to expel

some air from the carboy through the DryTrap air

lock (a one-way valve); thereby, creating a slight

vacuum inside the output carboy.

- Partially open the

carboy valve, until the remaining liquid has been

drawn into the output carboy. If some liquid remains

in the tubing, repeat these last two

steps.

| | | |

|

Bottling

BetterBottle SimpleFlo valves are designed so a

standard 3/8" bottling stem with a valve tip will fit into the

outlet. This makes it convenient to bottle and rack at the same time

– without any pumps or siphons. Contact with oxygen can be minimized

by maintaining an inert gas blanket over the wine or beer in the

BetterBottle carboy and flushing each bottle with the gas just

before it is filled. |

|

Cleaning Up

BetterBottle carboys are more easily

washed and sanitized than glass carboys, because BetterBottle carboys are

so light weight and the surface of the special PET from which they are

made is non-porous and hydrophobic. For details see

the Wash/Sanitize section, under the Technical tab at the

top of this page.

Stiff brushes, abrasive scouring pads, and

cleansers should never be required, or

used.

|