|

Unbreakable The fact that BetterBottle carboys are essentially

unbreakable in normal use is a major reason for their popularity.

Most glass carboys used in winemaking and brewing are made of soft glass

(soda-lime glass), because soft glass carboys are so very much less

expensive than hard glass (borosilicate glass) carboys. Soft glass carboys

are fragile, even if they have been properly heat annealed to remove all

strain, which is not always the case. There is no way to really know the

tensile (i.e., stretch) strength of the glass with any degree of

certainty, even when the carboys are new. And simple use will make things

much more unpredictable. Wear and tear scratches and micro cracks in the

surface of the glass dramatically reduce its tensile strength. Soft glass

dissolves in water; not rapidly, but more rapidly under caustic

conditions, such as soaking in a caustic detergent. Micro cracks develop

as the glass dissolves. Simply lifting a full glass carboy by its neck can

break the neck off. Just setting a full glass carboy on the floor or on a

counter can cause the bottom to crack. One person reported losing a really

great Merlot, just before bottling, when his happy labrador wagged its

tail against the carboy. So many people have had

such experiences that tales of the disasters are a staple of home

winemaking and brewing gallows humor. But if you are seriously

injured, or in any way liable, glass carboys are no laughing matter. A

glass carboy, especially one filled with liquid, will explode into

razor-sharp shrapnel when dropped.

Unlike glass carboys, shipping BetterBottle carboys does not

require costly packaging, special handling, or extra insurance. The cost

of packing and shipping a glass carboy can be as much the cost of the

carboy itself. This is an especially serious problem for

mail-order/Internet retailers, because customers often have the impression

that the high shipping and handling charges amount to gouging:

"Why do we charge handling fees for glass

bottles and carboys? Because we use a lot of time and packing materials

to get them ready for shipment. We individually bubble-wrap each bottle!

Look at the way we pack our bottles! When we pack your glass, it gets to

you in one piece. We've tried shipping glass bottles and fermenters in

their original boxes, but the rate of breakage was very high. Moreover,

shipping insurance won't cover broken glass unless it's surrounded by 2

inches of cushioning, so broken glass shipped in the original box means

you're out of luck trying to get a refund. The handling/shipping fees

that we charge barely cover the cost of the packing materials and labor

required." Quote from the Web site of a dealer

Less taste and odor ? The

special PET resins used to make BetterBottle carboys and fittings are pure

and impart no odors or tastes; whereas, rubber and soft plastic stoppers,

hoses, and siphon tubes used with glass carboys are notorious for

contributing and transferring flavors. Use the Technical tab at the

top of page to access Flavor Scalping.

Permeability

Of all the types of plastics that can be

made into bottles and carboys, only special types of polyethylene

terephthalate (PET) have been successfully used to make containers for

carbonated beverages. The reason is simple only these special types of

PET are sufficiently impermeable to keep carbonation (i.e., carbon

dioxide) in and the oxygen out. BetterBottle fermentation carboys are made

of a unique, scientifically tested PET and they are specially manufactured

so that oxygen permeability is negligible. Use the Technical tab at the

top of page to access an informative discussion of

Permeability.

BetterBottle PET carboys are slightly more

permeable than glass; however, it would be a mistake to assume that using

a glass carboy will guarantee superior results. It is important to think

of a glass carboy as just one part of complete fermenting system

that also includes an air lock, a stopper, some hose, a racking

cane etc. In typical use, more oxygen diffuses through, or leaks by,

liquid-filled air locks and many types of stoppers (most notably silicone

rubber stoppers) than diffuses through the walls of BetterBottle

carboys and fittings. Moreover, every time a stopper is removed from a

glass carboy in order to perform a test or to make an adjustment, a

considerable amount of oxygen enters the wine or beer. Air contains about

20% oxygen. If the head space (ullage) in a carboy is just 200 ml, 40 ml

of oxygen will enter every time the stopper is removed. In fact, much more

oxygen will enter. Oxygen reacts very rapidly with wine and beer, which

essentially sucks up oxygen. Racking from an open glass carboy with a

siphon tube or pump will also expose the wine or beer to a large amount of

oxygen. In actual practice, BetterBottle carboys are equal to, or

better than, glass carboys, because BetterBottle fittings make it

convenient to control the extent to which wine or beer are exposed to

oxygen. (Use the Product

Information tab at the top of page

to access Tips on Usage.)

Extremely light weight and easy to handle

BetterBottle carboys weigh only ~1.5 lbs (

~0.68 Kg) empty and can be easily held by their necks using just one hand.

They are designed with externally textured ribs in their sides, so they

are easy to handle when full, and their necks are strong enough to permit

the safe use of red, clamp-on, or blue, snap-on, handles. (See

Product Information tab at the top of this page.) Glass carboys weigh about

ten times as much and they are difficult and dangerous to handle, empty or

full. Extremely light weight and easy to handle

BetterBottle carboys weigh only ~1.5 lbs (

~0.68 Kg) empty and can be easily held by their necks using just one hand.

They are designed with externally textured ribs in their sides, so they

are easy to handle when full, and their necks are strong enough to permit

the safe use of red, clamp-on, or blue, snap-on, handles. (See

Product Information tab at the top of this page.) Glass carboys weigh about

ten times as much and they are difficult and dangerous to handle, empty or

full.

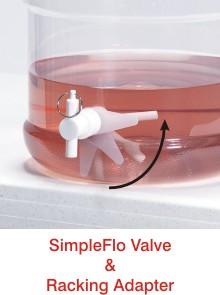

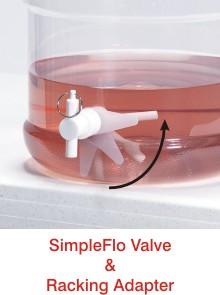

Racking outlets with SimpleFlo valve

BetterBottle carboys are available ported,

so they can be fitted with a racking adapter and SimpleFlo valve. Racking

wine or beer under oxygen-free conditions is as easy as rotating the

internal stem of the adapter to just above the level of any sediment and

opening the valve. Gravity does the rest no siphon is necessary. Porting

is simply not a practical option for inexpensive, soft glass

carboys Racking outlets with SimpleFlo valve

BetterBottle carboys are available ported,

so they can be fitted with a racking adapter and SimpleFlo valve. Racking

wine or beer under oxygen-free conditions is as easy as rotating the

internal stem of the adapter to just above the level of any sediment and

opening the valve. Gravity does the rest no siphon is necessary. Porting

is simply not a practical option for inexpensive, soft glass

carboys

Thom Cannell, the Projects column

editor for Brew Your Own, liked the idea of a carboy with a spigot

so much that he wrote a lengthy column describing how to install a plastic

spigot into the side of a glass carboy. [Brew Your Own, May-June 2003, pp 53-58].

The technique he described requires about $100 dollars worth of diamond

glass drills, an electric drill, and plenty of patience. High-Q, Inc., of

which BetterBottle is a division, drills precision holes in the sides of

borosilicate glass carboys on a regular basis in order to produce its

103C-G containers, which are used for storing high-purity water in

research and medical laboratories. And High-Q engineers commend Mr.

Cannell for his excellent description. However, the engineers are quite

certain that bottles prepared as Mr. Cannell describes will be

exceptionally fragile. The costly borosilicate carboys that High-Q uses

have walls nearly 3/8" thick; whereas, the walls of inexpensive soft-glass

(soda-lime glass) carboys are likely to be uneven and as thin as 1/8".

Moreover, following the drilling operation, High-Q re-anneals its carboys

in expensive high-temperature ovens in order to remove any strain

(i.e., tension in the glass structure created by the drilling). When glass

contains strain, it is prone to cracking.

Wide, precise opening

Glass carboys have relatively narrow (~30 mm) neck openings, making these

carboys difficult to fill and clean. The inside surfaces of their necks

are also likely to be uneven, making leaks and jammed stoppers a constant

problem. BetterBottle carboys have wide (44 mm), precise openings. The

consistency of the openings means that rubber stoppers fit better and it

is also possible to provide tough PET closures that have reliable O-ring

seals. These closures are more easily and quickly cleaned and sanitized

than rubber stoppers. (See Product

Information tab) Wide, precise opening

Glass carboys have relatively narrow (~30 mm) neck openings, making these

carboys difficult to fill and clean. The inside surfaces of their necks

are also likely to be uneven, making leaks and jammed stoppers a constant

problem. BetterBottle carboys have wide (44 mm), precise openings. The

consistency of the openings means that rubber stoppers fit better and it

is also possible to provide tough PET closures that have reliable O-ring

seals. These closures are more easily and quickly cleaned and sanitized

than rubber stoppers. (See Product

Information tab)

Easily cleaned/sanitized

BetterBottle carboys are more easily washed and sanitized than glass

carboys. Glass is hydrophilic and scums created during fermentation tend

to stick so tightly to the walls of glass carboys that stiff brushes and

plenty of elbow grease are necessary to loosen them. Strong bleach is

often required to oxidize residual organic films. By contrast, the surface

of the special PET from which BetterBottle carboys and fittings are made

is non-porous and hydrophobic. Hot water, a good bottle cleaning

detergent, and some soaking will separate films from the walls of

BetterBottle carboys, without brushing. Also, rinsing a BetterBottle

carboy by holding it upside down in one hand and spraying a jet of water

up against the bottom with a hose nozzle is easy and effective. Don't try

that with a glass carboy! Use the Technical tab at the

top of page to access the Wash/Sanitize

section. Easily cleaned/sanitized

BetterBottle carboys are more easily washed and sanitized than glass

carboys. Glass is hydrophilic and scums created during fermentation tend

to stick so tightly to the walls of glass carboys that stiff brushes and

plenty of elbow grease are necessary to loosen them. Strong bleach is

often required to oxidize residual organic films. By contrast, the surface

of the special PET from which BetterBottle carboys and fittings are made

is non-porous and hydrophobic. Hot water, a good bottle cleaning

detergent, and some soaking will separate films from the walls of

BetterBottle carboys, without brushing. Also, rinsing a BetterBottle

carboy by holding it upside down in one hand and spraying a jet of water

up against the bottom with a hose nozzle is easy and effective. Don't try

that with a glass carboy! Use the Technical tab at the

top of page to access the Wash/Sanitize

section.

Easily stored

Because BetterBottle carboys are so light

weight, they are easy to stack in an out of the way place when they are

not being used.

|